Tool and die makers in India | Plastic Mould Manufacturer

15/1 Rama Road

Kirti Nagar Delhi-110015 India

+91 8883912346

asia@hongyijig.com

Certified

ISO 9001:2015

AUTOMOTIVE

INJECTIONMOULD

- AUTOMOTIVE ENGINEERING COMPONENTS (TIER-1)

- LIGHTNING 4 WHEELERS

- EXTERIOR PANELS

- CABLE PROTECTING COMPONENTS

- ENGINE COVERS

- FIXURES

CASE STUDY

PROTECTOR DASH

Introduction:

Approach:

Outcome:

Conclusion:

CASE STUDY

PROTECTOR DASH

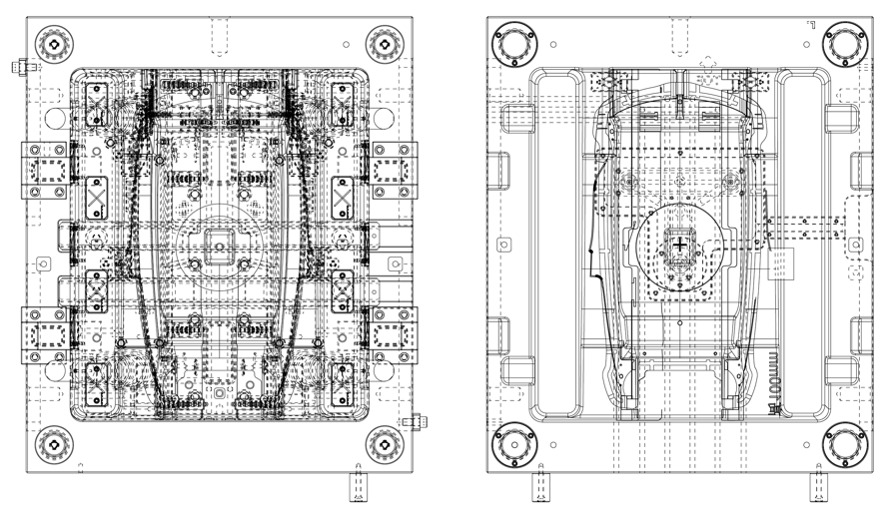

Development of Protector Dash for KIA Motors

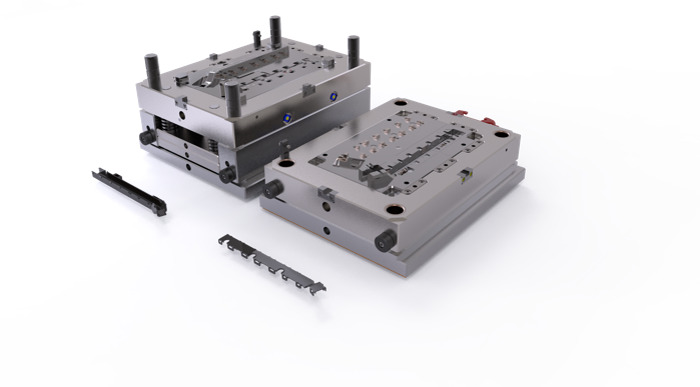

Injection mould Solution for Cable Protector

Introduction:

Approach:

Outcome:

Conclusion:

CASE STUDY

PROTECTOR DASH

Development of Protector Dash for KIA Motors

Injection mould Solution for Cable Protector

CASE STUDY

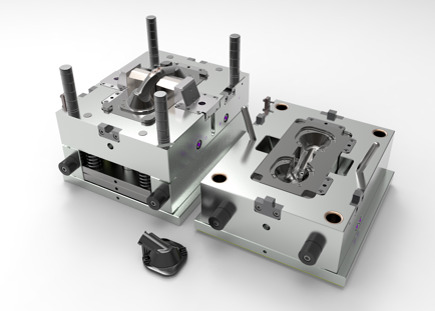

ACTUATOR HOUSING

Introduction:

Challenge:

Solution:

CASE STUDY

CABLE PROTECTORS

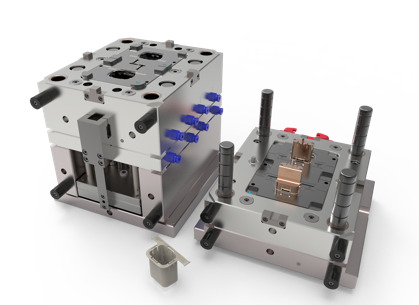

Injection mould development for Latch | Housing

The Solution for Critical

Automotive Safety Components (OEM)

Injection Moulds for Latch (Actuator Housing)

Result:

CASE STUDY

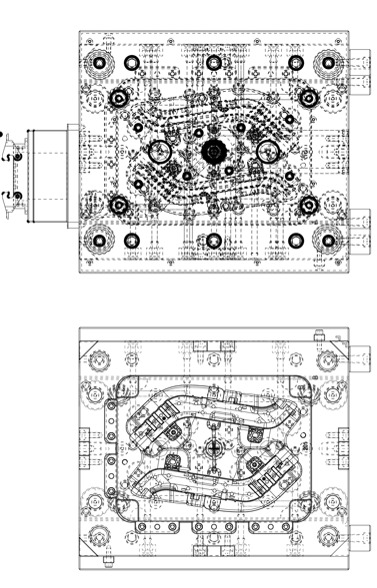

PROTECTOR BODY

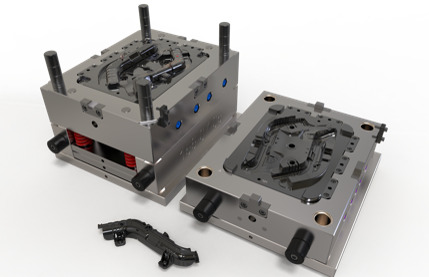

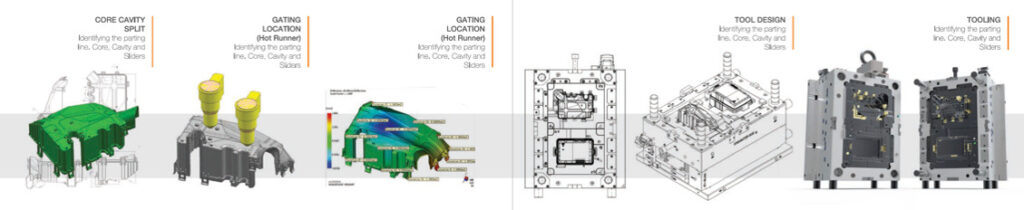

Automotive Cable Protector Components

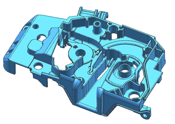

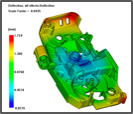

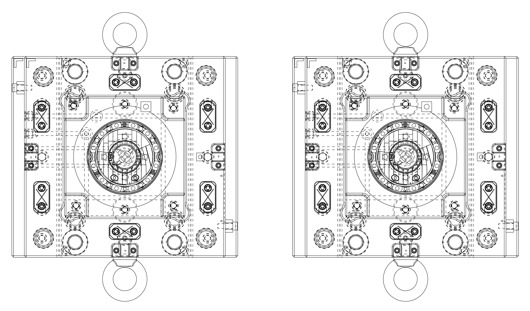

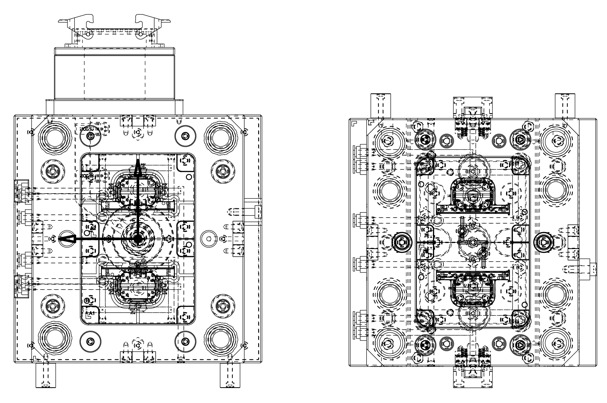

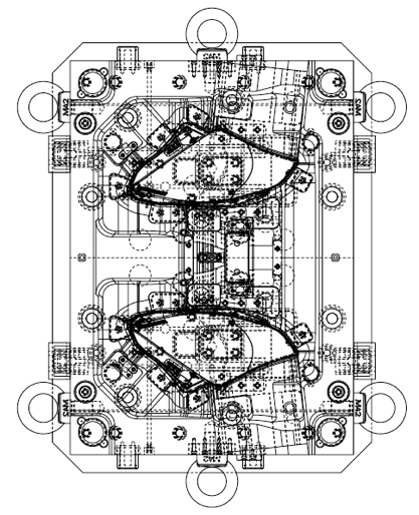

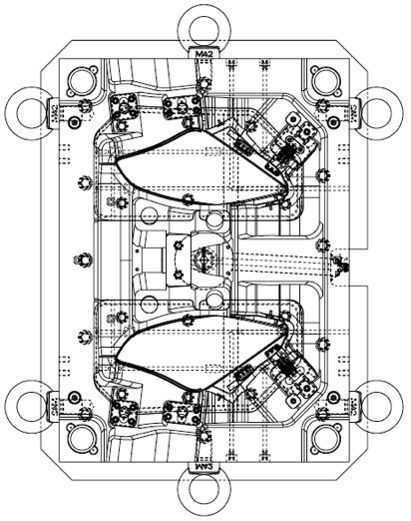

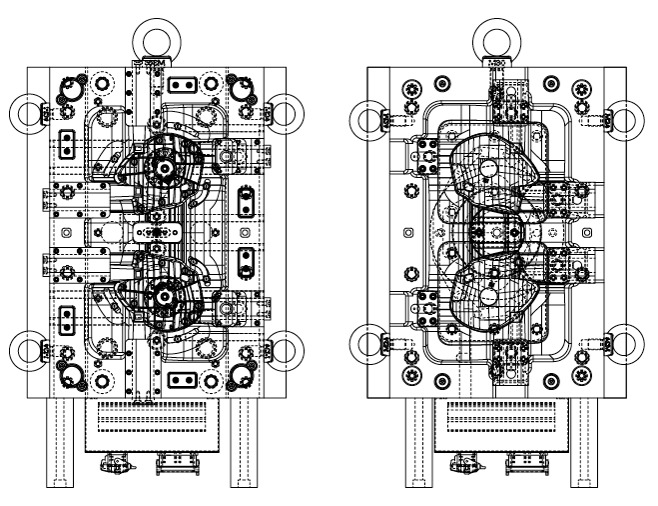

Challenge: The customer provided a basic 3D drawing without any draft angles and requested to develop the injection mould for the part. They wanted the team to understand the application of the part and prepare a 2D drawing with GD&T.

Solution: The team at the injection mould development company first understood the application of the part and captured the important functional dimensions. They then modified the 3D CAD data by adding draft angles while maintaining the important dimensions. The team received approval on the drawings and began tool manufacturing activities. The injection mould tooling material used was H-13 with two drops hot runner on the top surface. It took 30 days for the first trial, and the total project took three months to deliver.

Result: The injection mould development company successfully developed the injection mould for Kyungshin Industrial Motherson Ltd.’s Protector Cover Body, meeting all of their requirements and specifications. The company was satisfied with the result and the quality of the injection mould, which contributed to their production process.

CASE STUDY

PROTECTOR BODY

Development of Protector Body for KIA Motors

Injection mould Solution for Cable Protector Components

CASE STUDY

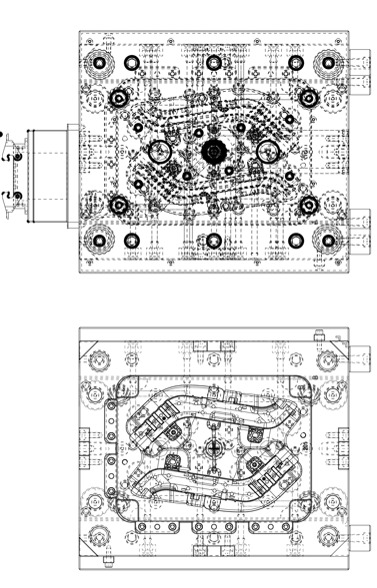

CABLE PROTECTORS

Introduction:

Outcome:

CASE STUDY

CABLE PROTECTORS

Injection mould development for Cable Dash

The Solution for Engineering & Moulds

Conclusion:

CASE STUDY

PROTECTOR BODY

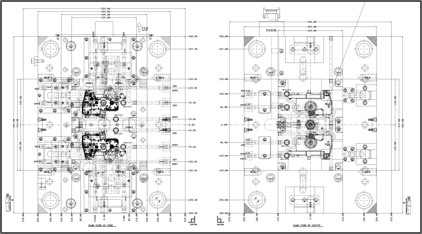

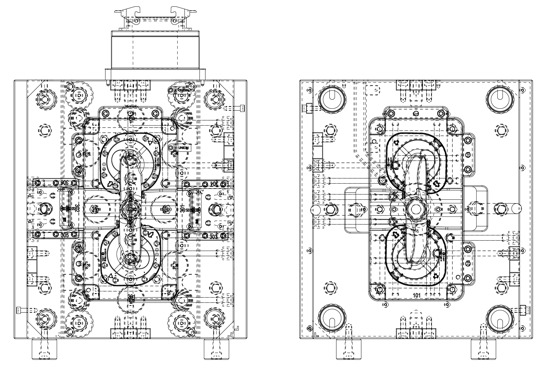

Client: KIML

Client’s Client: KIA Motors

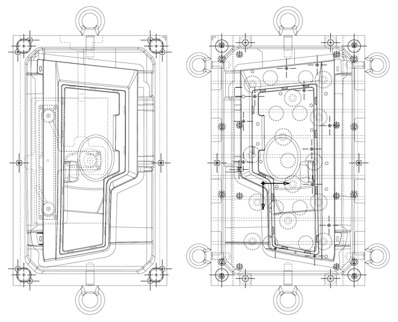

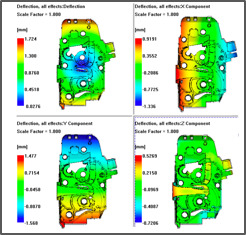

Scope of Work: Corrected the Part Design and Added Draft Angles, DFM, Moldflow, Tool Design

Tooling Time: 35 days

Total Development Time: 3 months

Challenge:

Our challenge was to develop an injection mould for the HCL Upper Cover + Lower Cover components with high-quality standards required for automotive components, within a tight timeline.

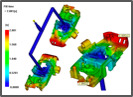

Solution:

We conducted DFM and Moldflow analysis to ensure optimized design for injection moulding, corrected design issues, added necessary draft angles, selected appropriate materials and manufacturing methods, and completed the tooling process in 35 days.

Result:

CASE STUDY

PROTECTOR BODY

Development of Protector Body for KIA Motors

Injection mould Solution for Cable Protector Components

CASE STUDY

CABLE PROTECTORS

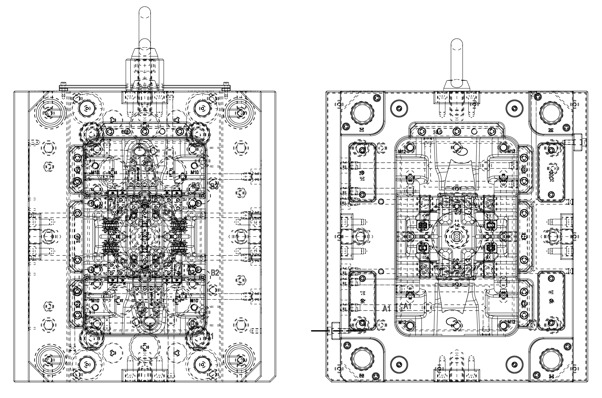

Tooling Lead Time: 45 days

Challenge:

CASE STUDY

CABLE PROTECTORS

Injection mould development forCable Dash

The Solution for Engineering & Moulds

Solution:

Result:

CASE STUDY

AUTOMOTIVE ENGG.

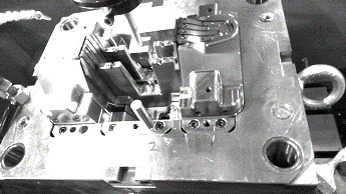

Introduction:

Approach:

Outcome:

Conclusion:

CASE STUDY

AUTOMOTIVE ENGG.

Injection mould Development for HALTER - BMW

The Solution for CriticalProfiles

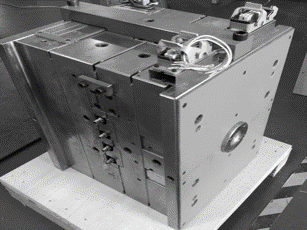

CASE STUDY

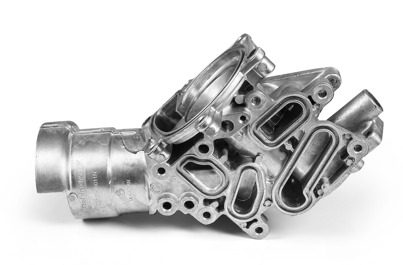

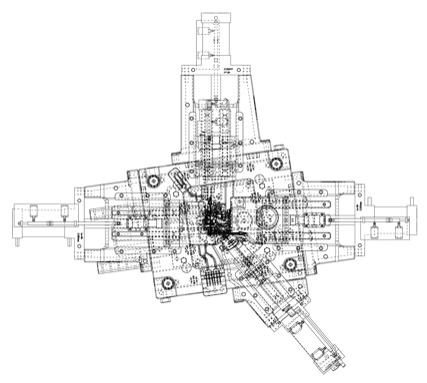

PDC | ENGINE FILTER

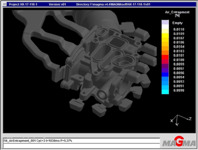

Challenge:

Solution:

CASE STUDY

PDC | ENGINE FILTER

PDC Mould Development for Engine Filter | Mahindra & Mahindra

The Solution for Pressure Die Casting Dies - UFI FILTER

Results:

Conclusion:

CASE STUDY

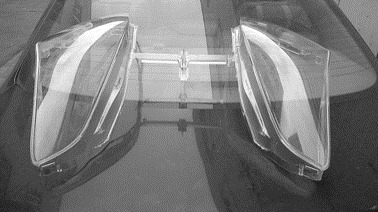

HEADLIGHT PROJECT

"Reverse Engineering and Injection Mould Development for Baleno Headlight Project"

CASE STUDY

HEADLAMP REFLECTOR

Introduction:

CASE STUDY

HEADLAMP REFLECTOR

BMC mould development for Reflector component

The Solution for Engineering & Moulds of Baleno Headlamp

Approach:

CASE STUDY

HEADLAMP

Outcome:

Conclusion:

CASE STUDY

HEADLAMP

Development of Headlamp Housing

The Solution for Baleno Headlamp

CASE STUDY

HEADLAMP

Introduction:

Approach:

Outcome:

CASE STUDY

HEADLAMP

Injection mould development for Headlamp

Head Lamp for Sonalika Tractors

Conclusion:

CASE STUDY

TRUCK PANELS

CASE STUDY

Truck Panels

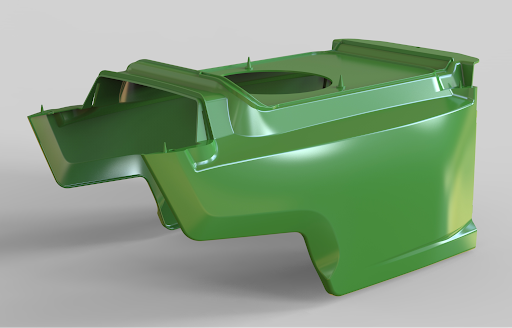

Outcome: Our expertise in reverse engineering, prototype development, and injection moulding helped us deliver high-quality moulds for our customer. The moulds were made using 738H material, ensuring the durability of the product.

Conclusion: Our team’s dedication and expertise helped us to meet the requirements of our American-based customer in the tractor replacement automotive market. We are proud to have delivered moulds that met the required quality standards and ensured the durability of the product.

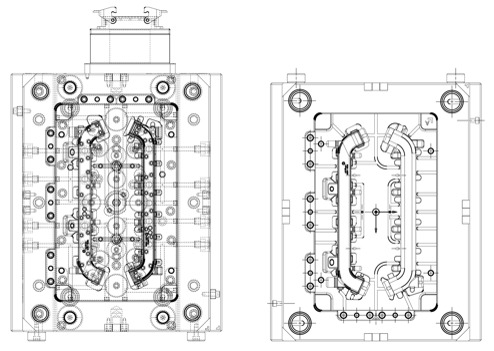

CASE STUDY

INJECTION MOULDS

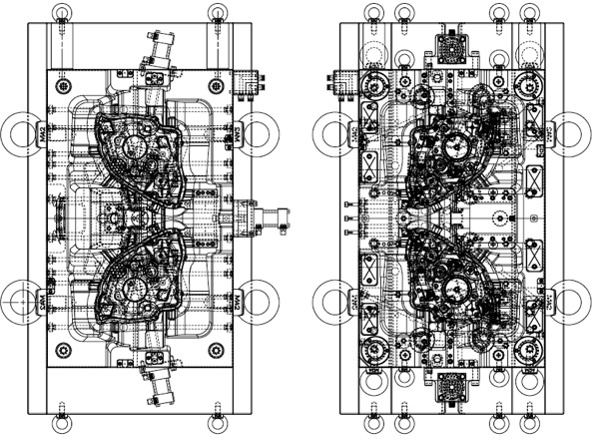

Introduction: Our company developed injection moulds for an American-based customer in the tractor replacement automotive market. We conducted reverse engineering of the components, created a prototype, and did functional checks on the vehicle.

Approach: Once the design and drawings were confirmed, we started working on DFM, Moldflow analysis, and Tool design. We used 738H material for the moulds to maintain the product shine. It took 5 months to deliver the moulds for production.

Outcome: Our expertise in reverse engineering, prototype development, and injection moulding helped us deliver high-quality moulds for our customer. The moulds were made using 738H material, ensuring the durability of the product.

Conclusion: Our team’s dedication and expertise helped us to meet the requirements of our American-based customer in the tractor replacement automotive market. We are proud to have delivered moulds that met the required quality standards and ensured the durability of the product.