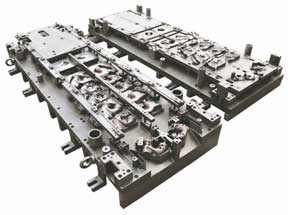

Tooling is a specialized area of manufacturing engineering which comprises of analysis, planning, design, construction and application of tools, methods and procedures necessary to increase manufacturing productivity. We believe in quality of tool design and that is enhanced through comprehensive internal inspections that are carried out to ensure maximum accuracy during the designing of tools. As one of the field of expertise HONGYI JIG designs tools that create impressive and user-friendly designs of a tool that gives instant success. It is a place where client can experience hassle free tool design. We ensure total customer satisfaction and that puts us ahead to set up a wide client base, which will be augmented on regular basis.. Hongyi JIG provides manufacturing solutions in different domains of Stamping dies Progressive dies, Transfer Automated dies, Line dies, Inspection Fixtures, Welding fixtures etc.

Progressive Dies

- Medical

- Consumer Product

- Automotive

- Packaging

- Electronics

- Home Appliances

- Electrocal Appliances

Transfer Dies

- Progressive Dies

- Transfer Dies

- Line Dies System

- Progressive Dies

- Checking Fixtures

Welding Fixtures

- Turned Components

- CNC Milled Components

- Short Term Production

- Metal / Non Metal

Checking Fixtures

- Aluminium Die Cast

- Zinc Die

- Automotive

- Electricals

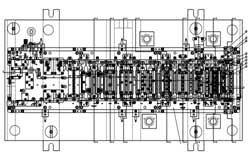

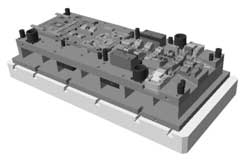

Progressive Dies, Transfer Dies, Single Operation Dies

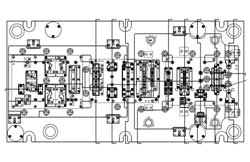

Sheet Metal Tool Design

3D Design and manufacturing drawing for Sheet metal components

Simulation

3D/2D Sheet metal Die Design and Detailing (Tandem Press, Transfer and progressive Dies)

3D Design and Detailing of Inspection fixtures.

Our Engineers are flexible in adopting any customer standard guidelines.

Our Engineers have experience of working onsite (India & China)

The experience level of our Engineers in this domain, range between 6 years to 10 years along with the Tool making hands on experience.

PROGRESSIVE DIES . TRANSFER DIES . SINGLE OPERATION DIES

Checking Fixtures, CMM Holding Fixtures and Gauges, Welding Fixtures

Avail from us a wide range of Checking Fixtures that is manufactured in accordance with international standards. Wide range of Checking Fixtures is made available by us for various applications like checking of light panels, profiles, cushion seats and other parts. The use of latest designing and production technologies ensures that each Checking Fixture offered by us is geared for offering the best performance.

Working Process for Fixtures

- 1. Project Kick Off

- 2. GD&T;, Technical Agreement

- 3. Design

- 4. Customer Review

- 5. Drawings in 3D and 2D

- 6. Preparation & Processing

- 7. Part Inspection

- 8. Assembly

- 9. CMM

- 10.Gauge Modifications

- 11. Re-Examination

- 12. Packaging & Shipping

Tooling with Workmanship

Project management is the key to the success and quality of the products A Project Engineer who has rich knowledge in tooling and injection molding is appointed for each project. All of them have a good command of English. The project engineers will be responsible to follow up tooling schedule and timely report to the customer on any issues and progress of the project he is handling. The project engineer also guarantees that customer’s technical requirement is followed.

Communication

Assuring customer’s project is produced to customer’s standards and requests. During this period we keep you updated about sending you the progress of tool manufacturing through an excel sheet and pictures of current process. It gives a clear idea about your project progress and a confidence of time bound deliveries avoiding all the surprises

On Time Delivery

We assure the on time delivery as per planned The lead time for T0 which we quote, usually starts from the approval on the tool designs till the first mold trial. We arrange sending you the T1 samples for approval in 3 working days, Most of the time T1 samples do not need to be modified still in case if there is some modification it is always subjected to the possibilities and work for the time. It takes usually 4-7 working days to finish the mold. .We deliver the molds in wood packaging according the terms of deliveries which may EXW, FOB or CIF.